Steady-state recycling (SSR) chromatography

Background

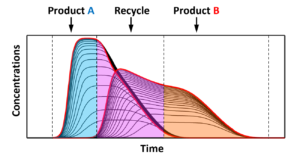

Steady-state recycling (SSR) chromatography is a simple, but powerful chromatographic operating mode. It is particularly suited for separating mixtures into two fractions. In an SSR process, large amounts of feed mixture are injected. From the resulting overloaded elution profiles, only the sufficiently pure leading and trailing edges are withdrawn as product fractions, while the remaining unresolved mixture fraction is recycled. In each cycle, a given amount of fresh mixture is added to the recycle fraction. This operation causes the process to attain a periodic steady state after a few cycles, characterized by much higher concentrations than found in classical batch chromatography.

In comparison to separations by batch chromatography, SSR processes achieve superior performance. They allow for reducing solvent consumption, increased yield, and often also increased productivity. Although the process uses a single column only, the performance achievable by SSR units is close to that of the much more complex SMB chromatography.

The main challenge of implementing SSR used to be the design in terms of adjusting the correct fractionation times for achieving the desired product purities. This problem has been resolved using equilibrium theory in a close collaboration between Malte Kaspereit and Prof. Tuomo Sainio (Lappeenranta-Lahti University of Technology, Finland). You’ll find more details on this in the publications below.

Selected publications on SSR chromatography

- Dienstbier, J., Schmölder, J., Burlacu, R., Liers, F., & Kaspereit, M. (2020). Global optimization of batch and steady-state recycling chromatography based on the equilibrium model. Computers & Chemical Engineering, 135, 106687. https://doi.org/10.1016/j.compchemeng.2019.106687

- Schmölder, J., & Kaspereit, M. (2020). A Modular Framework for the Modelling and Optimization of Advanced Chromatographic Processes. Processes, 8. https://doi.org/10.3390/pr8010065

- Kaspereit, M., & Schmidt-Traub, H. (2020). Process concepts. In Henner Schmit-Traub, Michael Schulte, Andreas Seidel-Morgenstern (Eds.), Preparative Chromatography: Third Edition. John Wiley & Sons, Ltd..

- von Langermann, J., Kaspereit, M., Shakeri, M., Lorenz, H., Hedberg, M., Jones, M.J.,... Seidel-Morgenstern, A. (2012). Design of an integrated process of chromatography, crystallization and racemization for the resolution of 2′,6′-pipecoloxylidide (PPX). Organic Process Research & Development, 16(2), 343-352. https://doi.org/10.1021/op200268h

- Kaspereit, M., & Sainio, T. (2011). Simplified design of steady-state recycling chromatography under ideal and nonideal conditions. Chemical Engineering Science, 66(21), 5428-5438. https://doi.org/10.1016/j.ces.2011.07.058

- Siitonen, J., Sainio, T., & Kaspereit, M. (2011). Theoretical analysis of steady state recycling chromatography with solvent removal. Separation and Purification Technology, 78(1), 21-32. https://doi.org/10.1016/j.seppur.2011.01.013

- Kaspereit, M. (2011). Optimal Synthesis and Design of Advanced Chromatographic Process Concepts. Magdeburg: Otto-von-Guericke Universität.

- Sainio, T., & Kaspereit, M. (2009). Analysis of steady state recycling chromatography using equilibrium theory. Separation and Purification Technology, 66(1), 9-18. https://doi.org/10.1016/j.seppur.2008.12.005